Electrical Options for Lubrication Systems

Automate Your Lubrication Process with These Electrical Options

Enhance the functionality and precision of your lubrication systems with A-S Manufacturing's comprehensive range of electrical options. From programmable timers and digital counters for automated control to safety features like low lubricant level float controls, our selection ensures optimal performance and reliability. Discover components designed to automate lubricant delivery, improve safety, and streamline your industrial operations.

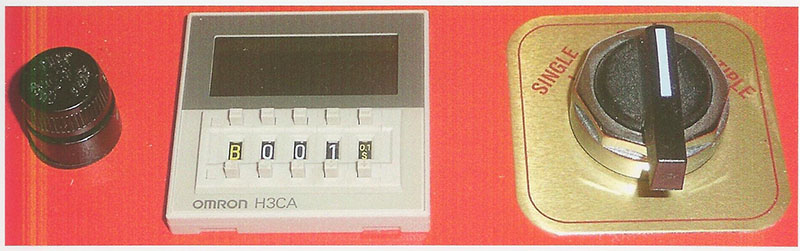

Programmable Repeat Cycle Timer

It is recommended for use when large amounts of lubricant are needed or when long stock feed lengths require multiple sprays to achieve desired lubricant coverage.

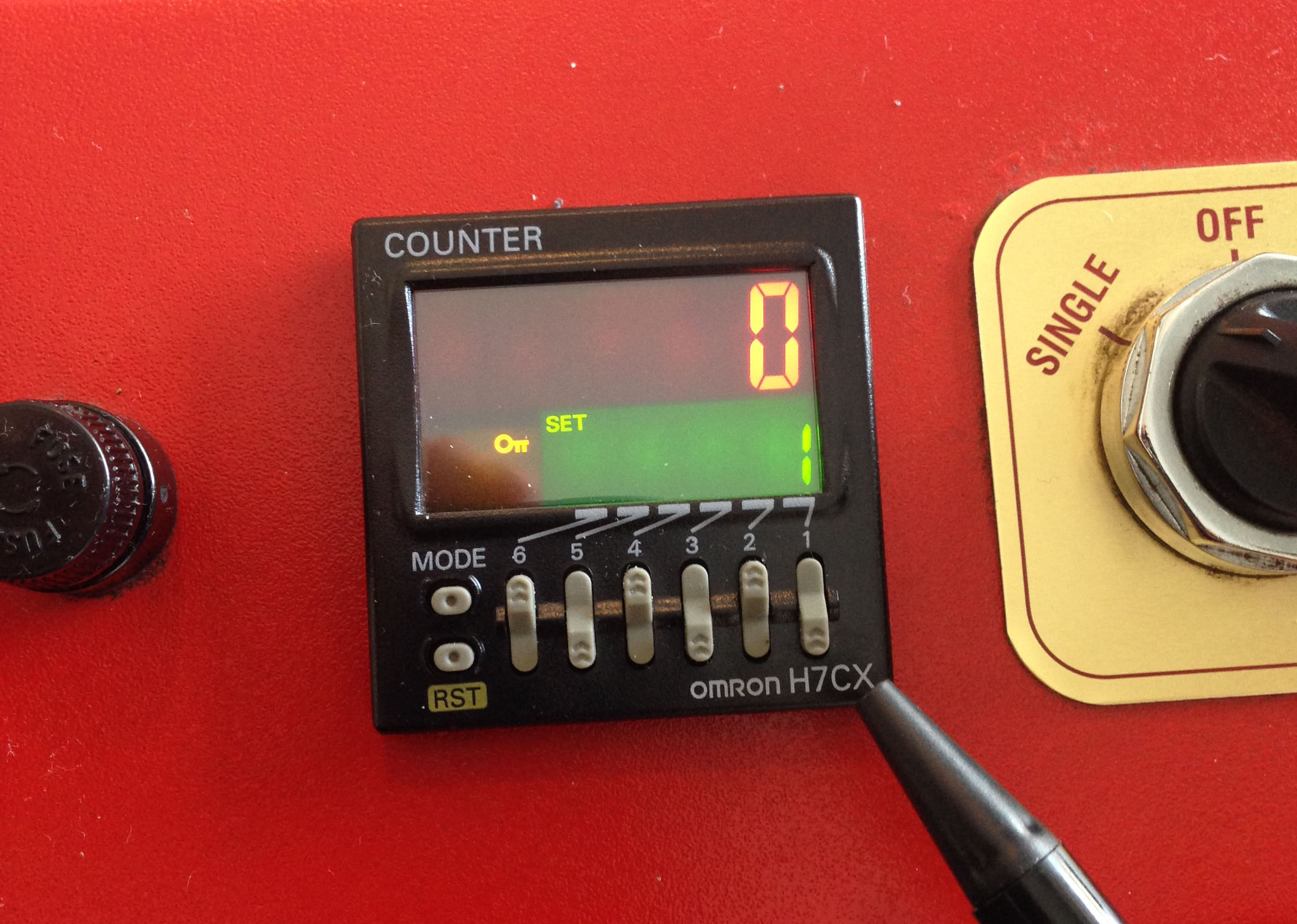

Programmable Digital Counter

An electrical device used when lubricant is not required with every stroke of the press. It can be easily programmed to deliver lubricant on desired stroke counts.

Low Lubricant Level Float Control

(pictured with the lubricant filters)

An electrical “fail safe” device that signals the operator when the lubricant level in the reservoir is low. The spray system automatically turns off until the reservoir is re-filled. The red “low lube level light” illuminates to alert the operator of the low lube level condition A relay is provided to allow interfacing with the top-stop circuitry of the press, preventing dry die runs.

Stainless-Steel Filters

This sleek design is 1/2” diameter, 3” high (4-1/4” including Quick Connect Fitting) & 100 Mesh filtration.

Download Literature

Download Literature

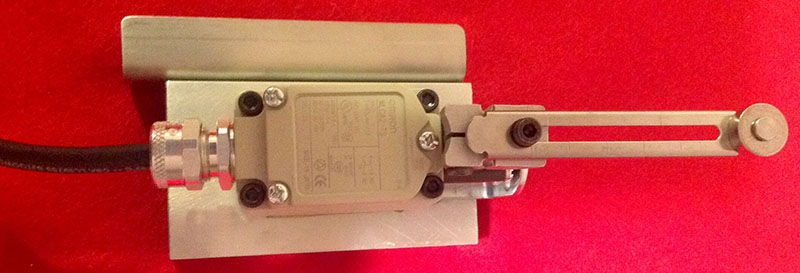

Magnetic Based Limit Switch

A Limit Switch is mounted on a Heavy-Duty Magnet for quick set up. It is utilized to signal the operation of the spray system when provisions are not available in the existing press circuitry.

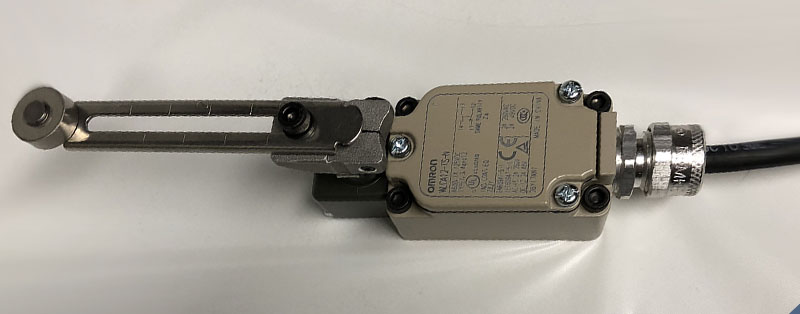

Limit Switch Without Magnetic Base

It is utilized to signal the operation of the spray system when provisions are not available in the existing press circuitry.

Foot Control Switch

Used in hand fed operations or when precise automatic timing is not available. The Foot Control Switch can be used to manually operate the spray system.

Fluid Agitation System for Reservoir

Continuously circulates the lubricant in the reservoir to minimize lubricant separation of water-soluble products.

15' Electrical Cord & Plug

Brings power to the terminal strip of the spray system. All additional wiring occurs from there.